- ARAB NEWS

- 01 Aug 2025

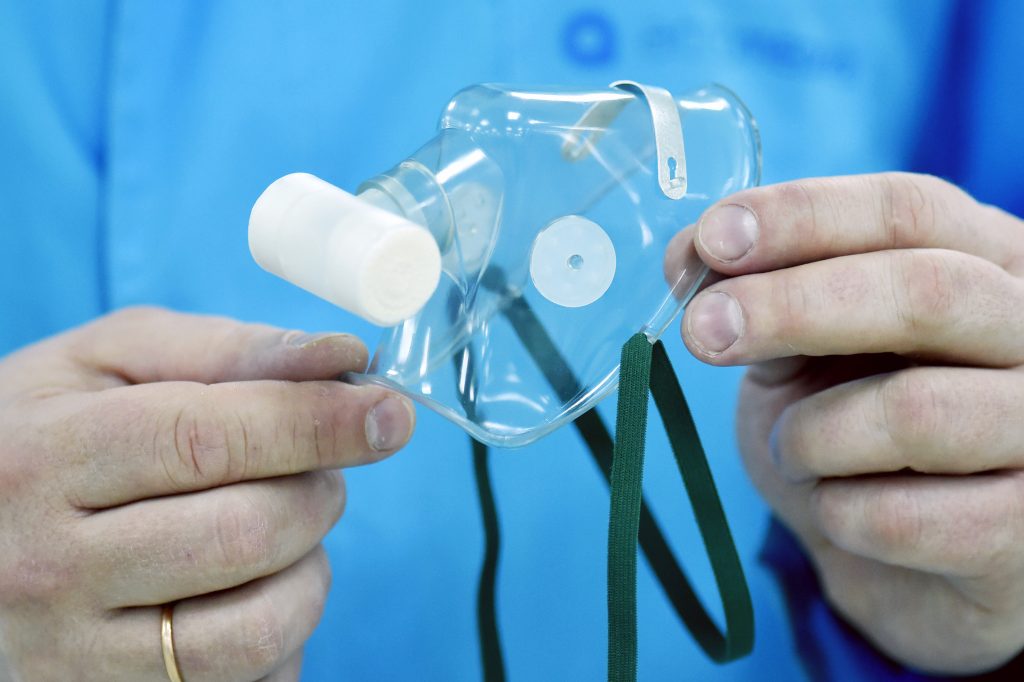

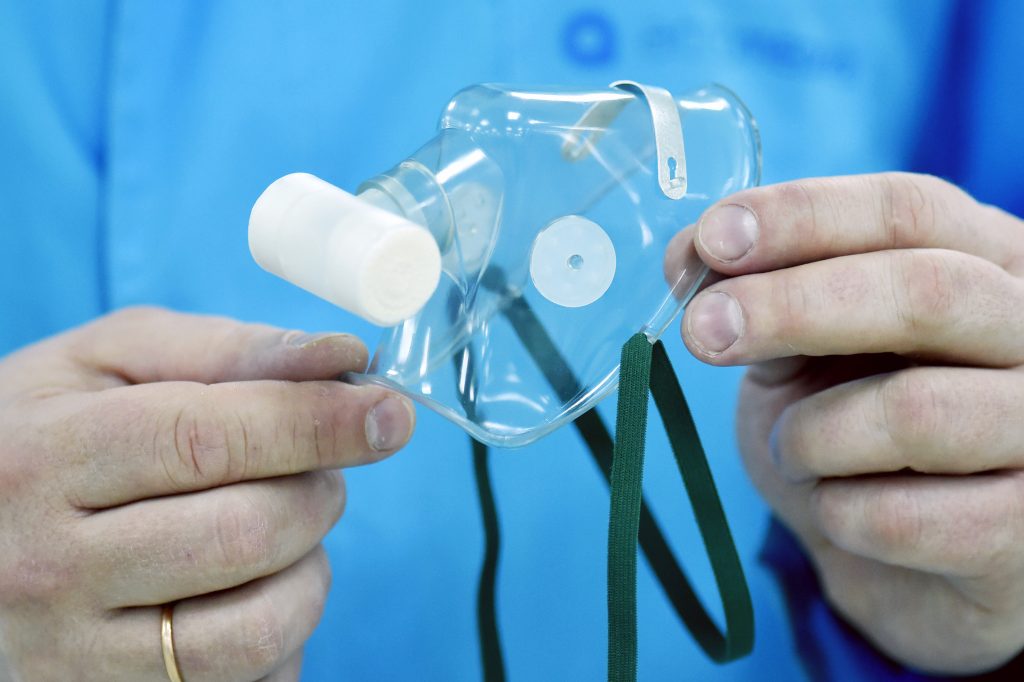

TOKYO: Concerns are growing over Japan's ability to boost the production of such medical equipment as artificial ventilators that are necessary for treating people with severe coronavirus symptoms amid a rapid increase of such patients across the country.

The Japanese government has sought support from medical equipment makers as well as automakers and electronics makers for increasing the production of such medical devices.

But companies outside the medical industry face obstacles as manufacturing medical devices requires a high degree of safety.

Major Japanese medical device supplier Terumo Corp. has started boosting its production of artificial lungs, called extracorporeal membrane oxygenation, or ECMO, devices, designed to replace the functions of lungs from patients suffering from severe COVID-19 symptoms.

ECMO devices oxygenate blood taken from patients with severe respiratory failure and pump it back into the body.

Terumo, which holds a 70 share of the Japanese ECMO market, is operating its plant in Shizuoka Prefecture, central Japan, seven days a week to make the machines.

The company plans to make a hundred and several tens of units over the next several months, equivalent to its annual production for ECMO machines.

Medical equipment maker Nipro Corp., which makes parts used in ECMO machines, is seeing a surge in the number of inquiries about the products from home and abroad.

Meanwhile, Japanese Prime Minister Shinzo Abe has said that his government has secured 15,000 units of artificial ventilators to treat COVID-19 patients and aims to increase the number to 20,000 units.

But the greater part of the ventilators used in Japan are imported, and most domestic makers of such products are small and midsize companies. Japan thus has little scope for increasing the production of such devices, industry sources said.

Sanko Manufacturing Co., based in the city of Saitama, eastern Japan, and Koken Medical Co., headquartered in Tokyo, have started increasing their production of anesthesia and ambulance ventilators, respectively. But their products cannot be used at intensive care units, they say.

An official of Nihon Kohden Corp., which imports ventilators designed for ICUs, said that "as demand (for ventilators) is growing globally, we are not sure whether we will be able to secure sufficient supplies from this point."

In the United States, major automakers such as General Motors Co. have said that they will manufacture ventilators.

The Japanese government has sought support from businesses in various industrial sectors to join forces to boost the production of such medical devices.

The government earmarked 8.8 billion yen in its emergency economic stimulus package adopted last week to finance subsidies for boosting the medical equipment production.

Toyota Motor Corp. plans to provide its know-how on improving production efficiency to medical equipment makers.

Despite hopes for Toyota's possible entry into the production of ventilators, President Akio Toyoda remains cautious, saying it is not easy to manufacture products that are directly related to people's lives.

Hiroaki Nakanishi, chairman of the Japan Business Federation, or Keidanren, who is also chairman of electronics and machinery giant Hitachi Ltd., has said that "companies outside the medical industry cannot easily make (medical devices) due to regulations" aimed at securing product quality and safety.

On cross-industry cooperation, an official at a small medical equipment manufacturer said that "although we have received offers to send engineers, it is difficult to entrust such people (without experience) with manufacturing (medical products)."

JIJI Press