- ARAB NEWS

- 18 Jul 2025

Carla Chahrour

The world’s first shipment of blue ammonia was dispatched from Saudi Arabia to Japan on Sep. 27, 2020 for use in a power station for the production of zero-carbon power generation, paving the way for the further utilization of hydrogen in the energy system.

The Saudi-Japanese collaboration is part of a pilot project, conducted by the Institute of Energy Economics, Japan (IEEJ) and oil company Saudi Aramco in partnership with Saudi Basic Industries Corp. (SABIC).

The collaboration is important for both countries as Japan aims to be a world-leader in the use of hydrogen, while Saudi Arabia, the world’s largest oil producer, wants to diversify its energy mix with plans on emerging as a global force in clean power.

In the Paris climate deal, Japan pledged to reduce its greenhouse gas emissions by 26 percent by 2030, from 2013 levels. It also plans to “lead the world in utilizing hydrogen” for clean energy production, which is contained in ammonia.

“Blue ammonia is critical to Japan’s zero carbon emission ambitions to sustain the balance between the environment and the economy. About 10% of power in Japan can be generated by 30 million tons of blue ammonia. We can start with co-firing blue ammonia in existing power stations, eventually transitioning to single firing with 100% blue ammonia,” IEEJ chairman and CEO Masakazu Toyoda said in a release.

In an earlier interview with Arab News Japan, Toyoyda explained that Japan is currently heavily dependent on energy imports, which mostly consists of fossil fuels, specifically oil. This was excaberated after the closure of Japan’s nuclear plans due to the Fukushima nuclear accident in 2011, which forced Japan to shift its energy mix and lead to an increase in the consumption of natural gas, oil, and renewable energy to replace the portion of the nuclear energy share.

“At this moment, we depend on fossil oil for a high percentage in our energy mix. This is the result of the Fukushima nuclear accident” Toyoda said.

Moreover, he explained that the reason behind Japan’s interest in the use of ammonia instead of other sustainable energy sources such as solar power was due to the unavailability of sufficient sunlight and wind power.

“Unlike the Middle East, we don’t have much sunshine in Japan, and unlike North Europe, we don’t have stable wind power. We have typhoons that can be very strong and can’t utilize windmills unfortunately. This is why the ammonia business is important for the Japanese government as a source of power,” Toyoda said.

The project is also important for Saudi Arabia to showcase its increased focus on sustainable energy as a cornerstone in building the solution to the current unsustainable energy model. The Kingdom has placed energy transitions, which include a gradual shift from fossil fuels towards hydrogen-based, low-carbon energy sources at the heart of their development strategies with an aim to diversify their energy production. Additionally, it opens significant investment opportunities in the energy sector while simultaneously creating a potentially important addition to the Kingdom’s export commodity portfolio.

Ammonia is a chemical compound that contains one nitrogen atom bonded to three hydrogen atoms. Blue ammonia is a feedstock for blue hydrogen, which is a version of the fuel created from fossil fuel sources, where the carbon emissions are captured and stored.

The advantage ammonia has over fossil fuels is that it releases no carbon dioxide (CO2) when combusted in a thermal power plant, and it is easier to transport, which means that it has “the potential to make a significant contribution to an affordable and reliable low-carbon energy future,” according to Saudi Aramco.

“Ammonia is a very good carrier for hydrogen because it has the convenience and practicality of being transported as a liquid with more favorable pressure and temperature compared to pure hydrogen and that gives it a huge advantage as it lowers the cost of transporting ammonia,” Saudi Aramco said.

The production of 40 tonnes of blue ammonia by Saudi Aramco and SABIC leveraged existing infrastructure as the blue ammonia supply chain begins at the Saudi Aramco oil and gas production facilities, where hydrocarbons are processed into blue ammonia at Jubail, the largest industrial city in Saudi Arabia located in the Eastern province.

The Saudi-Japan blue ammonia supply network demonstration utilized two different pathways to reduce direct atmospheric emissions of carbon dioxide from ammonia production: Carbon Capture and Utilization (CCU) and Enhanced Oil Recovery (EOL).

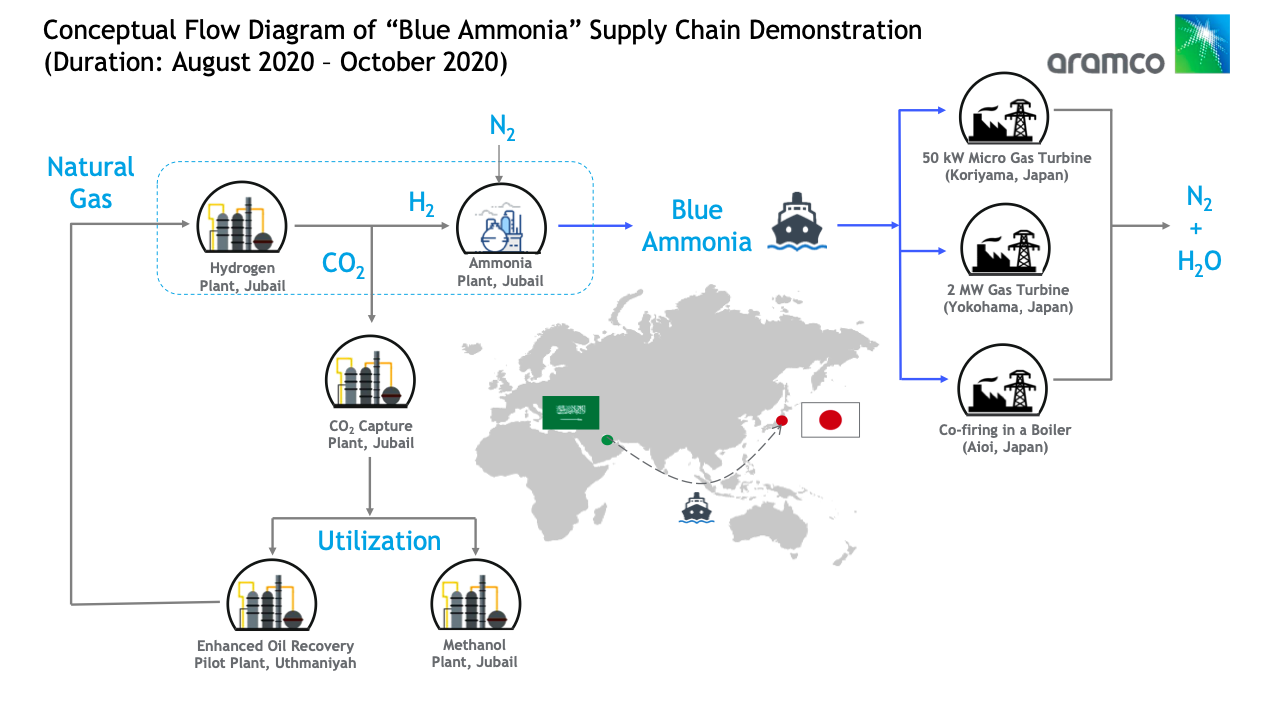

Schematic of the blue ammonia supply chain demonstration. (Armaco)

Schematic of the blue ammonia supply chain demonstration. (Armaco)In carbon capture and utilization, a portion of carbon dioxide produced at an ammonia plant, namely, the Saudi Arabian Fertilizer Company (SAFCO), a SABIC affiliate, which operates five ammonia plants in Jubail, with a total capacity of about 3.6 million tonnes per year, is transported to SABIC’s Ibn-Sina methanol plant using an existing carbon dioxide pipeline. Once there, carbon dioxide is used as feedstock for synthesizing methanol, according to the IEEJ’s demonstration of the blue ammonia supply chain.

For Enhanced Oil Recovery, carbon dioxide is captured at SABIC’s facility (SAFCO) and liquified for transportation in an ISO tanker. The carbon dioxide arrives at Hawiya, Saudi Arabia’s Natural Gas Liquefaction (NGL) plant. Here fractionation columns process a mixed stream of light hydrocarbons, separating them into pure fractions.

In 2015, a carbon dioxide recovery system was constructed and installed at the Hawiyah NGL plant as well as an 85 kilometers carbon dioxide pipeline from the plant to Uthmaniyah was also built. The Uthmaniyah Carbon Dioxide Enhanced Oil Recovery (CO2-EOR) Demonstration facility (owned and operated by Saudi Aramco) has maintained steady progress since it first became operational and involves the capture of 800,000 tonnes of carbon dioxide annually from the Hawiyah NGL Plant for use in enhanced oil operations.

In order for the carbon dioxide delivered from Jubail to be injected into the carbon dioxide pipeline that connects to the EOR facility, Saudi Aramco had to construct a carbon dioxide vaporization and transfer system. First, a red isolation valve is opened manually, then liquid carbon dioxide in the ISO tanker is passed through a vaporizer to turn the carbon dioxide back into a gaseous state. After that carbon dioxide gas that is discharged from the vaporizer is sent to the compressor section and when it arrives at the EOR facility, it is injected under pressure into the oil reservoir where it helps to enhance oil mobility.

This enables higher oil recovery while permanently storing part of the injected carbon dioxide into the reservoir itself. Through utilizing hydrocarbons, ammonia and carbon dioxide are produced. Then, through capturing and utilizing the carbon dioxide, blue ammonia is produced, according to the IEEJ’s demonstration of the blue ammonia supply chain.

Mitsubishi Corporation, which is representing IEEJ’s study team, worked with SABIC to monitor the transport logistics in partnership with JGC Corporation, Mitsubishi Heavy Industries Engineering, Mitsubishi Shipbuilding Co and UBE Industries.

In the case of the blue ammonia project, Saudi Aramco said in a statement that shipping challenges were overcome with 50 tonnes of carbon dioxide captured during the process, 30 tonnes of which was utilized in SABIC’s Ibn-Sina methanol plant. The remaining 20 tonnes were transported and injected into the Uthmaniyah oil field for Enhanced Oil Recovery.

Blue ammonia was then shipped Japan to generate power at three production sites: A plant in Aioi where ammonia wasco-fired with coal, a 2 megawatt (MW) plant in Yokohama, where the ammonia was co-fired with natural gas and a 50 kilowatt (kW) micro gas turbine site in Koriyama.

“The shipment is considered the first around the world, and it represents a crucial opportunity for Aramco to introduce hydrocarbons as a reliable and affordable source of low-carbon hydrogen and ammonia,” said Ahmad Al-Khowaiter, Chief Technology Officer, Saudi Aramco, according to Saudi media.

Fahad Al-Sherehy, SABIC’s Vice President of Energy Efficiency and Carbon Management, also said: “At SABIC, we can economically leverage our existing infrastructure for hydrogen and ammonia production with CO2 capture. Our experience in the full supply chain along with integrated petrochemicals facilities will play an important role in providing the world with the blue ammonia.”

The Saudi-Japan blue ammonia supply network involved a full value chain; including the conversion of hydrocarbons to hydrogen and then to ammonia, as well as the capture of associated carbon dioxide emissions.

Japan currently lies at the forefront of promoting a hydrogen economy and was one of the first countries to release a hydrogen strategy in December 2017, which outlined the vision for the country’s low carbon energy society of the future and the role of hydrogen in achieving this vision.

The Strategy includes an aim of developing commercial-scale international integrated hydrogen supply chains to import 300,000 tonnes of hydrogen annually by 2030 at ¥30/Nm3 (normal cubic meter) and a longer-term goal of 10 metric tonnes per year.

Hydrogen is also expected to assist Japan in reducing its dependence on foreign fossil fuels for energy and reducing greenhouse gas (GHG) emissions through the creation of a new carbon free industry.

As the urgency of climate change becomes more obvious and the energy matrix continues to evolve, Ammonia is facilitating the creation of new energy economies, with the Saudi-Japanese pilot project serving as one example through which ammonia can help supply the world’s increasing demand for energy through reliable and sustainable methods.